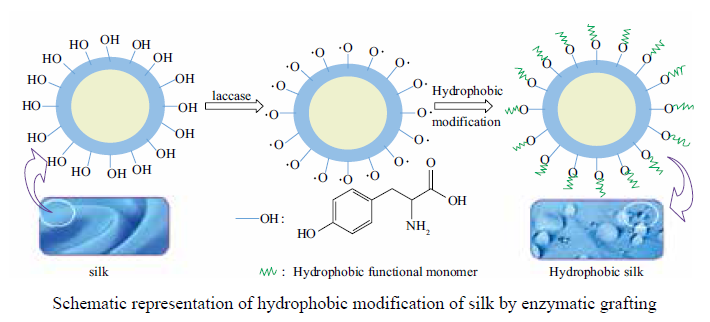

The hydrophobicity of silk fiber is relative poor, which greatly limits its application in many fields. Therefore, the study of hydrophobic modification of silk is of great significance. Herein, laccase was used as biocatalyst and lauryl gallate (DG) was used as monomer to modify silk via hydrophobic grafting in a special buffer solution. The reaction conditions were optimized, including the reaction time, pH, temperature, the dosages of laccase, monomers and Cu2+, and the media concentration. Fourier transformation infrared spectrum (FTIR), scanning electron microscopy (SEM), contact angle, water repellency, moisture regain, breaking strength and elongation of silk fabrics were used to analyze the structure and performance of silk before and after grafting. The experimental results show that, at the bath ratio of 1:50, real silk fabric can obtain better grafting rate at the temperature of 50 ℃, pH 4, laccase dosage of 2 U/mL, monomer dosage of 12 mmol/L, CuSO4 concentration of 15 mmol/L, DMP concentration of 0.15 mol/L and with processing time of 5 h. In addition, such treatment of silk via enzyme-catalyzed grafting modification will cause less fiber damage, and the modified silk fabric can achieve excellent hydrophobicity. Thus a new method for native protein fiber modification by enzymatic oxidation of phenolic hydroxyl groups of tyrosine triggering graft polymerization reaction has been proposed. This enzyme-catalyzed finishing of silk fiber is efficient, mild, energy-saving and environment-friendly, which can not only improve the quality of silk products, but also reduce the energy consumption of enterprises and the environmental protection pressure. Therefore, it has important application value.