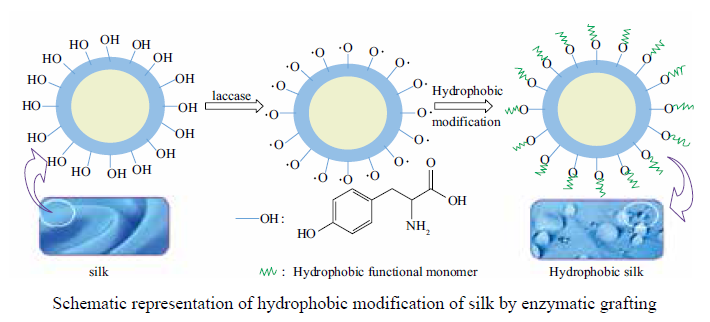

采用漆酶作为生物催化剂,以没食子酸月桂酯(DG)为单体对真丝进行了疏水改性研究。实验结果表明,在浴比1:50,温度50 ℃,pH 4,漆酶用量2 U/mL,单体用量12 mmol/L,Cu2+浓度15 mmol/L,2,6-二甲氧基苯酚(DMP) 0.15 mol/L,处理时间5 h条件下,真丝织物可获得较佳接枝率。通过红外光谱(FTIR)、扫描电镜(SEM)、拒水度、接触角、断裂强力等测试,对接枝前后的真丝结构及性能进行分析。结果显示,漆酶催化真丝接枝改性处理对纤维损伤较小,且改性后的真丝织物可获得优异疏水效果。本文将酶催化氧化酪氨酸的酚羟基引发接枝聚合反应的特点与真丝纤维功能改性有机结合,提出了一种天然蛋白纤维改性的新方法。此外,真丝纤维的酶法催化改性整理高效温和、节能环保,可在提高真丝产品品质的同时,降低企业能耗,缓解社会的环保压力,具有重要的应用价值。

The hydrophobicity of silk fiber is relative poor, which greatly limits its application in many fields. Therefore, the study of hydrophobic modification of silk is of great significance. Herein, laccase was used as biocatalyst and lauryl gallate (DG) was used as monomer to modify silk via hydrophobic grafting in a special buffer solution. The reaction conditions were optimized, including the reaction time, pH, temperature, the dosages of laccase, monomers and Cu2+, and the media concentration. Fourier transformation infrared spectrum (FTIR), scanning electron microscopy (SEM), contact angle, water repellency, moisture regain, breaking strength and elongation of silk fabrics were used to analyze the structure and performance of silk before and after grafting. The experimental results show that, at the bath ratio of 1:50, real silk fabric can obtain better grafting rate at the temperature of 50 ℃, pH 4, laccase dosage of 2 U/mL, monomer dosage of 12 mmol/L, CuSO4 concentration of 15 mmol/L, DMP concentration of 0.15 mol/L and with processing time of 5 h. In addition, such treatment of silk via enzyme-catalyzed grafting modification will cause less fiber damage, and the modified silk fabric can achieve excellent hydrophobicity. Thus a new method for native protein fiber modification by enzymatic oxidation of phenolic hydroxyl groups of tyrosine triggering graft polymerization reaction has been proposed. This enzyme-catalyzed finishing of silk fiber is efficient, mild, energy-saving and environment-friendly, which can not only improve the quality of silk products, but also reduce the energy consumption of enterprises and the environmental protection pressure. Therefore, it has important application value.