China Surfactant Detergent & Cosmetics ›› 2025, Vol. 55 ›› Issue (1): 1-11.doi: 10.3969/j.issn.2097-2806.2025.01.001

• Invited paper • Next Articles

Hua Xue1,Fengchun Liang1,Weili Yang1,Qun He1,Meirong Cai2,*( ),Feng Zhou2,Weifeng Bu1,2,*(

),Feng Zhou2,Weifeng Bu1,2,*( )

)

Received:2024-08-04

Online:2025-01-22

Published:2025-01-23

Contact:

E-mail: CLC Number:

Hua Xue, Fengchun Liang, Weili Yang, Qun He, Meirong Cai, Feng Zhou, Weifeng Bu. Boron-containing copolymers as environmentally friendly lubricant additives[J].China Surfactant Detergent & Cosmetics, 2025, 55(1): 1-11.

Tab. 1

Characterization and DLS data for boron-containing copolymers"

| n:m(feed ratio) | n':m' a (actual monomer ratio) | Mn,SECb/kDa | Dispersity (?)b | Hydrodynamic sizec/nm | |

|---|---|---|---|---|---|

| S1-r-B0 | 1:0 | 1:0 | 88 300 | 1.18 | 34 |

| S1-r-B1/3 | 3:1 | 0.12:1 | 75 600 | 1.40 | 31 |

| S1-r-B1 | 1:1 | 1:1.0 | 43 000 | 1.56 | 18 |

| S1-r-B2 | 1:2 | 1:1.3 | 31 300 | 1.85 | 9.7 |

| S1-r-B3 | 1:3 | 1:1.9 | 34 300 | 1.84 | 26 |

| S1-r-B5 | 1:5 | 1:3.1 | 39 400 | 1.47 | 52 |

| S1-r-B9 | 1:9 | 1:4.8 | 38 900 | 1.46 | — |

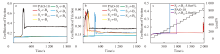

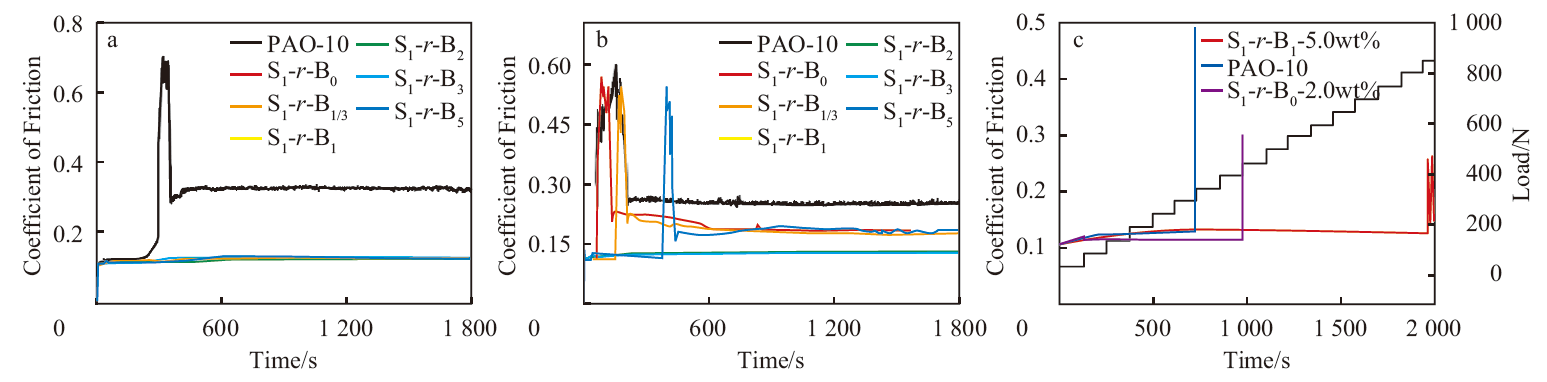

Fig. 3

Friction traces (a-c) of the oil solutions formed in PAO-10 by Sn-r-Bm at 200 N (a), 400 N (b), and load ramp tests of S1-r-B1 and S1-r-B0 (c). The concentration of macromolecular additives was controlled at 2.0wt% or 5.0wt%. The friction curves of PAO-10 were plotted together for comparable studies"

Fig. 5

Surface morphologies and depths of the wear scars lubricated by PAO 10 and S1-r-B1: 3D optical microscope images of the worn surfaces (200 N, PAO-10, a), (400 N, PAO-10, e), (200 N, S1-r-B1, i), and (400 N, S1-r-B1, m), wear scar section profiles obtained from the 3D optical microscopic images (200 N, PAO-10, b), (400 N, PAO-10, f), (200 N, S1-r-B1, j), and (400 N, S1-r-B1, n), SEM images of the worn surfaces (200 N, PAO-10, c), (400 N, PAO-10, j), (200 N, S1-r-B1, k), and (400 N, S1-r-B1, o), and enlargements of panels c, g, k, and o (200 N, PAO-10, d), (400 N, PAO-10, h), (200 N, S1-r-B1, l), and (400 N, S1-r-B1, p)"

Tab. 2

Wear volumes for steel discs lubricated by PAO-10 and Sn-r-Bm (n=1, m=0, 1/3, 1, 2, 3, 5) under a normal load of 400 N, an oscillation frequency of 25 Hz, and a stroke of 1 mm"

| Sample | Wear volume/μm3 | Decreasing percentage /% |

|---|---|---|

| PAO-10 | 6 308 591 | 0 |

| S1-r-B0 | 2 280 636 | 63.85 |

| S1-r-B1/3 | 1 480 626 | 76.53 |

| S1-r-B1 | 199 213 | 96.84 |

| S1-r-B2 | 231 523 | 96.33 |

| S1-r-B3 | 260 846 | 95.86 |

| S1-r-B5 | 2 275 452 | 63.93 |

| [1] | Rizvi Syed Q. A. A comprehensive review of lubricant chemistry, Technology, Selection, and Design[M]. ASTM International Publisher, New York, 2009. |

| [2] | Tung Simon C, McMillan Michael L. Automotive tribology overview of current advances and challenges for the future[J]. Tribology International, 2004, 37 (7) : 517-536. |

| [3] | Holmberg Kenneth, Andersson Peter, Erdemir Ali. Global energy consumption due to friction in passenger cars[J]. Tribology International, 2012, 47: 221-234. |

| [4] |

Ueda Mao, Spikes Hugh, Kadiric Amir. In-situ observations of the effect of the ZDDP tribofilm growth on micropitting[J]. Tribology International, 2019, 138: 342-352.

doi: 10.1016/j.triboint.2019.06.007 |

| [5] | Fujita H, Glovnea R P, Spikes H A. Study of zinc dialkydithiophosphate antiwear film formation and removal processes, Part Ⅰ: Experimental[J]. Tribology Transactions, 2005, 48 (4) : 558-566. |

| [6] | Guan Jiju, Xu Xuefeng, Hu Jiande. Preparation and action mechanism of inclusion complex of β-cyclodextrin and sulfurized isobutylene as additives in solution of polyethylene glycol-600[J]. Journal of Wuhan University of Technology-Materials Science, 2015, 30: 859-867. |

| [7] | Du Sen, Yue Wen, Wang Yanyan, et al. Synergistic effects between sulfurized-nanocrystallized 316L steel and MoDTC lubricating oil additive for improvement of tribological performances[J]. Tribology International, 2016, 94: 530-540. |

| [8] | Espejo Cayetano, Wang Chun, Thiébaut Benoît, et al. The role of MoDTC tribochemistry in engine tribology performance. A Raman microscopy investigation[J]. Tribology International, 2020, 150, 106366. |

| [9] | Yamamoto Y, Gondo S, Kamakura T, et al. Frictional characteristics of molybdenum dithiophosphates[J]. Wear, 1986, 112 (1) : 79-87. |

| [10] | Unnikrishnan R, Jain M C, Harinarayan A K, et al. Additive-additive interaction: an XPS study of the effect of ZDDP on the AW/EP characteristics of molybdenum based additives[J]. Wear, 2002, 252(3-4) : 240-249. |

| [11] | Spikes H. The history and mechanisms of ZDDP[J]. Tribology Letters, 2004, 17: 469-489. |

| [12] | Fu Zhiqiang, Lin Shumin, Tian Hezhong, et al. A comprehensive emission inventory of hazardous air pollutants from municipal solid waste incineration in China[J]. Science of the Total Environment, 2022, 826, 154212. |

| [13] | Gulzar M, Masjuki H H, Alabdulkarem A, et al. Chemically active oil filter to develop detergent free bio-based lubrication for diesel engine[J]. Energy, 2017, 124: 413-422. |

| [14] | Ullah S F, Glavatskih S, Antzutkin O N. Boron in tribology: from borates to ionic liquids[J]. Tribology Letters, 2013, 51: 281-301. |

| [15] | Li Jianchang, Li Zhipeng, Ren Tianhui, et al. Hydrolytic stability and tribological properties of N-containing heterocyclic borate esters as lubricant additives in rapeseed oil[J]. Tribology International, 2014, 73: 101-107. |

| [16] | Yan Jincan, Zeng Xiangqiong, van der Heide Emile, et al. The tribological performance and tribochemical analysis of novel borate esters as lubricant additives in rapeseed oil[J]. Tribology International, 2014, 71: 149-157. |

| [17] | Zheng Zhuoyuan, Cox McCord, Li Bin. Surface modification of hexagonal boron nitride nanomaterials: a review[J]. Journal of Materials Science, 2018, 53: 66-99. |

| [18] | Liu Ning, Tian Yumei, Yu Lianxiang, et al. Synthesis and surface modification of uniform barium borate nanorods for lubrication[J]. Journal of Alloys and Compounds, 2008, 466 (1-2) : 11-14. |

| [19] | Zheng Zhi, Shen Guangqiu, Wan Yong, et al. Synthesis, hydrolytic stability and tribological properties of novel borate esters containing nitrogen as lubricant additives[J]. Wear, 1998, 222: 135-144. |

| [20] | Li Weimin, Wu Yanxia, Wang Xiaobo, et al. Tribological study of boron-containing soybean lecithin as environmentally friendly lubricant additive in synthetic base fluids[J]. Tribology Letters, 2012, 47: 381-388. |

| [21] | Sharma B K, Doll K M, Heise G L, et al. Antiwear additive derived from soybean oil and boron utilized in a gear oil formulation[J]. Industrial & Engineering Chemistry Research, 2012, 51 (37) : 11941-11945. |

| [22] |

Röttger Max, Domenech Trystan, van der Weegen Rob, et al. High-performance vitrimers from commodity thermoplastics through dioxaborolane metathesis[J]. Science, 2017, 356: 62-65.

doi: 10.1126/science.aah5281 pmid: 28386008 |

| [23] | Rahman M A, Bowland C, Ge S, et al. Design of tough adhesive from commodity thermoplastics through dynamic crosslinking[J]. Science Advances, 2021, 7. |

| [24] | Chen Chengxiang, Yang Weili, Bai Yanyan, et al. Dynamic oil gels constructed by 1, 2-dithiolane-containing telechelic polymers: An efficient and versatile platform for fabricating polymer-inorganic composites toward tribological applications[J]. Chemical Engineering Journal, 2022, 430: 133097. |

| [25] | Liang Fengchun, Chen Chengxiang, Xue Hua, et al. Toward high-performance lubricants: Rational design and construction of supramolecular oil gels by amphiphilic telechelic polymers to stabilize two-dimensional nanomaterials in base oils[J]. Tribology International, 2023, 184: 108468. |

| [26] | Liang Fengchun, He Qun, Li Shanshan, et al. Colloidally stable graphite oleogels by pyrene-functionalized telechelic polymers for friction and wear reduction[J]. ACS Macro Letters, 2023, 12 (10) : 1345-1350. |

| [27] |

Makino H, Nishikawa T, Ouchi M. Elucidating monomer character of an alkenyl boronate through radical copolymerization leads to copolymer synthesis beyond the limitation of copolymerizability by side-chain replacement[J]. ACS Macro Letters, 2020, 9 (6) : 788-793.

doi: 10.1021/acsmacrolett.0c00287 pmid: 35648527 |

| [28] | NIST X-ray photoelectron spectroscopy database, NIST standard reference database number 20, version 4.1, national institute of standards and technology, Gaithersburg MD, 2012.https://doi.org/10.18434/T4T88K. |

| [29] | Yu Qiangliang, Fan Mingjin, Li Dongmei, et al. Thermoreversible gel lubricants through universal supramolecular assembly of a nonionic surfactant in a variety of base lubricating liquids[J]. ACS Applied Materials & Interfaces, 2014, 6 (18) : 15783-15794. |

| [30] | Wang Yurong, Yu Qiangliang, Bai Yanyan, et al. Self-constraint gel lubricants with high phase transition temperature[J]. ACS Sustainable Chemistry & Engineering, 2018, 6 (11) : 15801-15810. |

| [31] | Li Yuting, Lan Songyu, Liu Yazhou, et al. Construction of ternary PEG200-based DESs lubrication systems via tailoring tribo-chemistry[J]. Friction, 2024, 12: 655-669. |

| [32] | Wen Ping, Lei Yongzhen, Yan Qianqian, et al. Multilayer tribofilm: a unique structure to strengthen interface tribological behaviors[J]. ACS Applied Materials & Interfaces, 2021, 13 (9) : 11524-11534. |

| [33] | Wang Jiao, Li Zhipeng, Zhao Hui, et al. Synergistic effects between sulfur-and phosphorus-free organic molybdenums and ZDDP as lubricating additives in PAO 6[J]. Tribology International, 2022, 165: 107324. |

| [1] | Gao Dangge, Li Suirong, Wang Lili, Lv Bin, Zhao Jing. Properties of a fracturing fluid thickener synthesized by inverse emulsion polymerization based on water/isoamyl octanoate-white oil [J]. China Surfactant Detergent & Cosmetics, 2023, 53(6): 625-633. |

| [2] | Gao Dangge, Li Pengyu, Yu Shuzhen, Liu Wei, Lv Bin. Synthesis and washing aid properties of a polycarboxylate copolymer [J]. China Surfactant Detergent & Cosmetics, 2023, 53(3): 271-278. |

| [3] | Mai Jingzhang,Li Lin,He Jinqing,Li Zeyong. Study on the synthesis and application of thickening-fixing hybrid rheology modifier [J]. China Surfactant Detergent & Cosmetics, 2022, 52(9): 960-968. |

| [4] | Chen Qi,Ran Lijun,Chen Zhao,Cui Zhenggang. Study on the preparation of C16 Guerbet alcohol polyoxyalkylene ether sulfate and its interfacial properties [J]. China Surfactant Detergent & Cosmetics, 2022, 52(10): 1055-1061. |

| [5] | YU Ming-ying,WANG Jing,YANG Cheng,CAO Guang-qun. Preparation of sunscreening composite microspheres by Pickering emulsion polymerization [J]. China Surfactant Detergent & Cosmetics, 2021, 51(1): 38-43. |

| [6] | SHI Li-yan,YANG Ming-zhu,SONG Bing-lei,CUI Zheng-gang. Synthesis of a eugenol-based surfactant and its application in preparing nanospheres [J]. China Surfactant Detergent & Cosmetics, 2020, 50(6): 373-378. |

| [7] | LIU Yao,MA Jian-zhong,YANG Hai-en,CAO Rong-rong,ZHANG Kang,LYU Bin. Preparation of polyacrylamide microspheres by inverse emulsion method and their properties [J]. China Surfactant Detergent & Cosmetics, 2020, 50(4): 238-243. |

| [8] | KANG Wan-li,XIE An-qing,ZHOU Bo-bo,WANG Fang,ZHANG Xiang-feng,YANG Hong-bin. Study on the design and synthesis of amphiphilic polymers and their synergistic systems (II)Theories and methods of the synthesis of amphiphilic polymers [J]. China Surfactant Detergent & Cosmetics, 2020, 50(2): 86-91. |

| [9] | CAO Chong-mei,FAN Ye,FANG Yun,XIA Yong-mei. Investigation on fluorescence characteristics of nanodots prepared by aqueous polymerization of conjugated linoleic acid [J]. China Surfactant Detergent & Cosmetics, 2020, 50(12): 815-820. |

| [10] | YU Ming-ying,WANG Jing,YANG Cheng,CAO Guang-qun. Advances in the applications of Pickering emulsion in cosmetics [J]. China Surfactant Detergent & Cosmetics, 2019, 49(6): 398-402. |

| [11] | Jing-cheng TIAN,Yong-qiang SUN,Jian-guo GUO. Synthesis of fatty alcohol polyoxyethylene ether with narrow distribution [J]. China Surfactant Detergent & Cosmetics, 2019, 49(3): 174-177. |

| [12] | NI Zhuo,CHEN Shu-tian,ZHU Jin-pu. Microencapsulation of beeswax as a phase change material in polyurea by interfacial polymerization [J]. China Surfactant Detergent & Cosmetics, 2019, 49(12): 811-816. |

| [13] | LV Xi-ming,YANG Cheng. Preparation and characterization of alkyl-modified silicone elastomer microspheres [J]. China Surfactant Detergent & Cosmetics, 2018, 48(8): 439-443. |

| [14] | BAI Liang, YANG Xiu-quan, WU Zhi-yu. Study of physical and chemical properties of alkyl polyxylosidase [J]. China Surfactant Detergent & Cosmetics, 2018, 48(11): 622-626. |

| [15] | GUO Rui, WANG Ying-yue, GUO Yu. Synthesis and flocculation performance of hydrophobically associating cationic polyacrylamide [J]. China Surfactant Detergent & Cosmetics, 2017, 47(7): 374-378. |

|